Rotary Vacuum Paddle Dryer (RVPD)

Rotary Vacuum Paddle Dryer – RVPD Comprising of horizontal cylindrical shell with suitable ends, slow speed paddle agitator is designed for mixing, drying and discharging the products. This is used for making powder from wet cake or slurries, in batch type operation often under vacuum.

These dryers give drying, mixing and breaking effects simultaneously. Wet cake or slurry is fed through charging door, while the agitator is rotating in clockwise direction, Vacuum is applied in the dryer and heating media is circulated in the jacket.

Evaporation of moisture takes place under vacuum and vapors passes through the dust catcher into the condenser, where it is condensed and collected in the receiver.

Dried material is discharged through discharge valve. The lump breaker rods are provided to achieve good drying effect.

The unique quick opening discharge valve is operated by a hand wheel. This allows quick discharge of material and permits the dry product to be directly packed into convenient 25/50 kg bags or drums without loss of powder material.

Rotary Vacuum Paddle Dryer

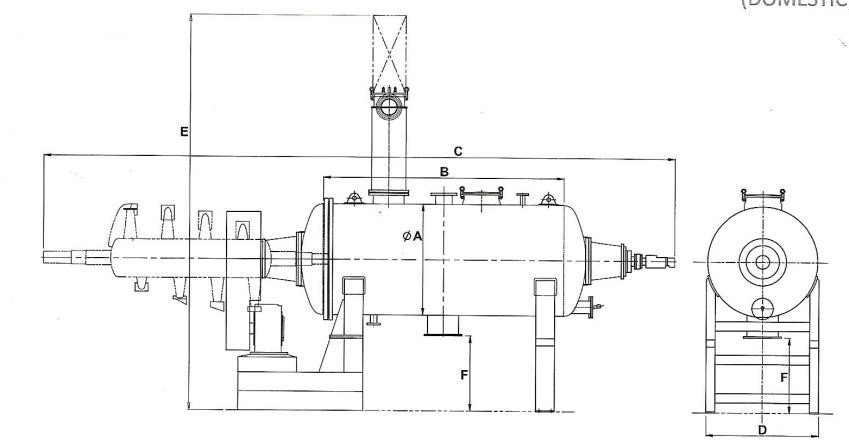

Standard Specifications

MODEL | GROSS VOLLUME (Liters ) | WORKING VOLLUME (LETRS)) |

MOTOR HP |

H.T.A (M) |

DIAMETE R (MM) |

LENGTH (MM) | INSTALLATIO N DATA |

Column2 |

Column3 | DISCHERGE CLEARANCE (MM) | |

|

|

| STADAR D | HIGH |

|

|

| WORKING LENGTH (MM) | BASE LENGTH (MM) | WORKING HEIGHT (MM) |

|

|

|

|

|

|

A |

B |

C |

D |

E |

F | |

DT-D -400 |

400 |

200 |

3 |

5 |

4.5 |

600 |

1450 |

5450 |

750 |

2950 |

750 |

DT-D – 500 |

500 |

250 |

5 |

10 |

5 |

625 |

1675 |

5880 |

750 |

2950 |

750 |

DT-D -1000 |

1000 |

500 |

7.5 |

15 |

8 |

750 |

2300 |

7150 |

900 |

2950 |

750 |

DT-D -1500 |

1500 |

750 |

10 |

20 |

9.5 |

900 |

2400 |

7800 |

1050 |

3350 |

1000 |

DT-D -2000 |

2000 |

1000 |

15 |

25 |

12.5 |

1000 |

2650 |

8600 |

1150 |

3700 |

1000 |

DT-D – 2500 |

2500 |

1250 |

20 |

30 |

14 |

1100 |

2750 |

8900 |

1250 |

3800 |

1000 |

DT-D -3000 |

3000 |

1500 |

20 |

30 |

15 |

1200 |

2775 |

9000 |

1350 |

3950 |

1000 |

DT-D -4000 |

4000 |

2000 |

25 |

30 |

18 |

1350 |

2850 |

9400 |

1500 |

4600 |

1000 |

DT-D -5000 |

5000 |

2500 |

30 |

40 |

21.5 |

1450 |

3200 |

10000 |

1600 |

4700 |

1000 |

DT-D -6000 |

6000 |

3000 |

30 |

40 |

25.5 |

1450 |

3900 |

10700 |

1600 |

4700 |

1000 |

DT-D -7500 |

7500 |

3750 |

40 |

50 |

29 |

1550 |

4245 |

12000 |

1700 |

4800 |

1000 |

DT-D -10000 |

10000 |

5000 |

40 |

50 |

33.5 |

1850 |

3950 |

12000 |

2000 |

5100 |

1000 |

DT-D -12500 |

12500 |

6250 |

60 |

75 |

40.5 |

1950 |

4475 |

13000 |

2100 |

5200 |

1000 |

DT-D -15000 | 15000 | 7500 | 60 | 75 | 43 | 2100 | 4500 | 13750 | 2250 | 4870 | 1000 |

Notes:-

- Consumed power is product specific user to specify power

- Data for reference only

- we reserve all the right to alter the designs without prior notice